What is Stamping in Stainless Steel Fabrication?

In the manufacturing industry, stainless steel parts are essential for a wide range of applications due to their strength, durability, and corrosion resistance. At Vim Model Manufacture LLC, we specialize in the stamping and bending of stainless steel parts, offering custom solutions that meet the specific needs of our clients. This article explores the processes involved, the benefits of stainless steel, and the applications of these versatile components.

"*" indicates required fields

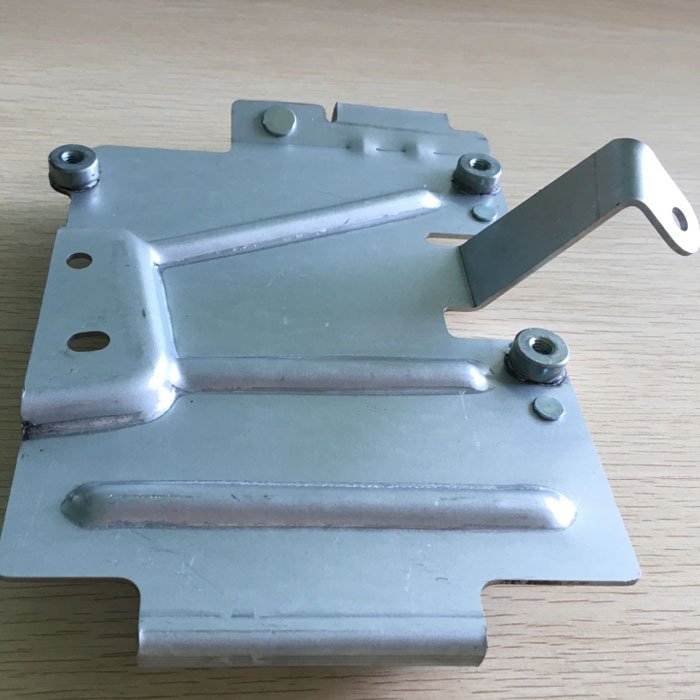

Stamping and Bending Stainless Steel Parts: Precision Fabrication for Diverse Applications

Introduction

In the manufacturing industry, stainless steel parts are essential for a wide range of applications due to their strength, durability, and corrosion resistance. At Vim Model Manufacture LLC, we specialize in the stamping and bending of stainless steel parts, offering custom solutions that meet the specific needs of our clients. This article explores the processes involved, the benefits of stainless steel, and the applications of these versatile components.

Understanding the Stamping Process

Metal stamping is a manufacturing technique that transforms flat stainless steel sheets into various shapes and components. This cold-forming process utilizes stamping presses and dies to create parts without the need for heating the material. Key benefits of stainless steel stamping include:

- High Efficiency: Stamping allows for the rapid production of large volumes of identical parts, making it ideal for high-demand applications.

- Cost-Effectiveness: The ability to produce parts in bulk reduces the cost per unit, making stainless steel stamping a budget-friendly option for manufacturers.

- Precision: Stamping provides high accuracy, ensuring that each part meets strict specifications and quality standards.

Bending Stainless Steel Parts

Bending is another critical process in the fabrication of stainless steel parts. This technique involves deforming the metal sheet into the desired shape using various methods, including:

- Press Brake Bending: This method uses a press brake machine to apply force, creating precise bends in the stainless steel sheet.

- Air Bending: A flexible method that allows for a range of angles and shapes, air bending is ideal for creating complex geometries.

- Coining: This technique applies a high amount of pressure to achieve precise bends and features, ensuring tight tolerances.

Bending stainless steel parts offers several advantages:

- Versatility: Stainless steel can be bent into various shapes and sizes, making it suitable for a wide range of applications.

- Strength: The inherent strength of stainless steel ensures that bent parts maintain their integrity and performance under stress.

Benefits of Using Stainless Steel

Stainless steel is a preferred material for many manufacturing processes due to its numerous benefits:

- Corrosion Resistance: Stainless steel’s resistance to rust and oxidation makes it ideal for use in harsh environments, including marine and industrial applications.

- Durability: Known for its strength and toughness, stainless steel parts can withstand significant wear and tear, ensuring a long service life.

- Aesthetic Appeal: The polished finish of stainless steel provides an attractive appearance, making it suitable for visible components in consumer products.

Applications of Stamped and Bent Stainless Steel Parts

Custom stainless steel parts produced through stamping and bending are used in various industries, including:

- Automotive: Components such as brackets, chassis parts, and exhaust systems.

- Aerospace: Structural components that require lightweight yet strong materials.

- Medical Devices: Surgical instruments and equipment that demand high hygiene standards.

- Construction: Architectural elements, supports, and fixtures that benefit from stainless steel’s durability.

Why Choose Vim Model Manufacture LLC?

At Vim Model Manufacture LLC, we are committed to delivering high-quality stamped and bent stainless steel parts tailored to your specific needs. Here’s why you should partner with us:

- Expertise: Our experienced team understands the intricacies of stainless steel fabrication, ensuring precision and quality in every project.

- Customization: We offer tailored solutions to meet your unique specifications, whether for prototypes or large production runs.

- Fast Turnaround: Our efficient processes allow us to deliver your parts quickly without compromising quality.

- Comprehensive Support: From design to delivery, our dedicated team is here to assist you at every step of the process.

Conclusion

Custom stamping and bending of stainless steel parts are vital for many industries, and at Vim Model Manufacture LLC, we pride ourselves on our ability to meet the diverse needs of our clients. With our advanced manufacturing capabilities and commitment to quality, we are your trusted partner for all your stainless steel fabrication needs.Contact us today to learn more about our stamping and bending services and how we can help bring your projects to life!

- Rapid Prototyping

- CNC machined parts

- CNC Turning

- Sheet metal

- Die Casting

- Small and large lot production of various quantities

- CMM inspection

- Finish ( Painting, Silkscreen, Sand Blasting, Electroplating, Anodize, etc )

- MOQ 1 pc

- 475 materials available

- 21 Surface Treatment available

- We have a staff of 118 professionals.

- 24 hours for prototype quote

- 4-24 hours to provide a quote for mass production

- 100% full size inspection

- Provide CMM inspection report & heat treatment inspection report & surface treatment certificate

- Many of our technicians have more than 10 years working experience, they are proficient in CNC 3-axis, CNC 4-axis, CNC 5-axis programming and all kinds of molds.

- Our engineering team can provide design suggestions if you need.

- Our engineering team can provide the most reasonable and economical mass production program according to different quantities.

- We can be shipped assembled if required.

- Robots

- Airplanes

- Medical devices

- Cars&Motorcycle

- Machinery

- design company

- Bicycles

- Watercraft

- Electronic

- Scientific Equipment

- Oil&Gas control systems

- Sinal receiving devices

- Optical devices

- Beauty

- Lighting

- Obtained ISO9001 certificate,laying the foundation for product quality.

- Sign a confidentiality agreement to protect customer information.

- Technicians are trained once a year to continuously optimize our skills.

- Project suggestions, optimize product structure.

- Free assembly.

- Your quotes are so fast and I like working with you guys.

- Your parts are so damned gorgeous,we just got some big box today.So Gorgeous.